CASE STUDY | A Lead-free Ultrasonic Transducer for Continuous Monitoring up to 400 °C (750 °F)

High-temperature monitoring using lead-free piezoceramics

Key Deliverables

- Novel lead-free piezoceramic materials developed for extreme environment ultrasonic systems, have mitigated the risk from changing legislation for new products.

- Lead-free piezoceramic successfully integrated into a high-temperature ultrasonic transducer for pipe wall thickness monitoring in harsh conditions.

- High piezoelectric activity and temperature capabilities have been maintained through a wide operating temperature range up to 400 °C (750 °F).

- UT compatible with existing manufacturing processes and equipment, successfully trend wall thickness measurements through temperature cycling, demonstrating long-term operational reliability.

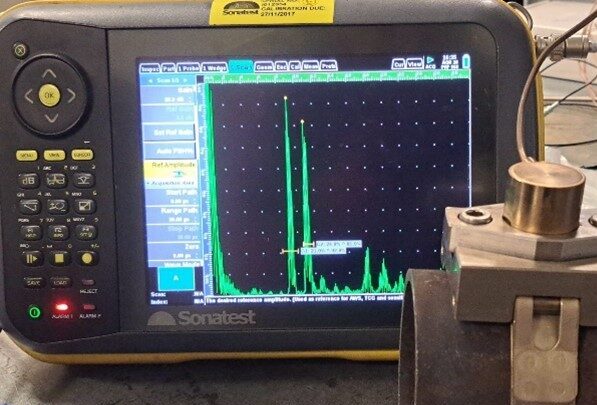

Figure 1: Wall thickness monitoring through temperature cycling, demonstrating long-term durability

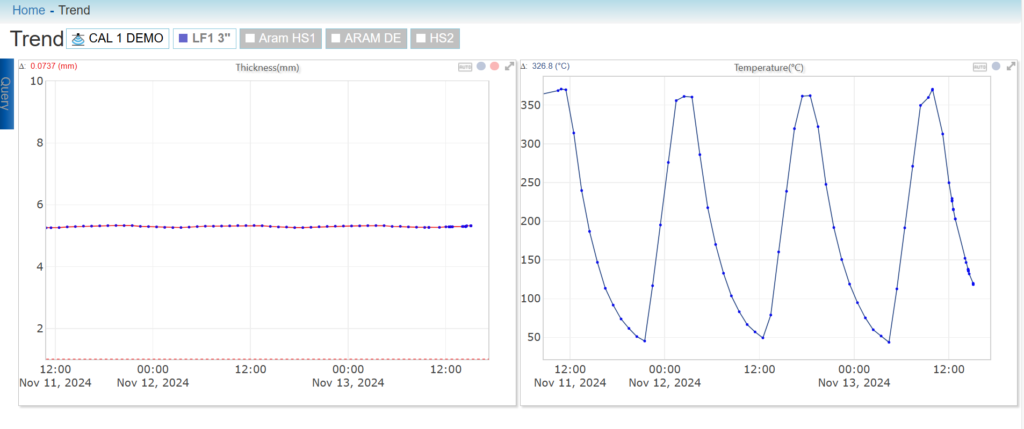

Figure 2: Lead-free HotSense™ probe connected to a 3″ pipe with a deployment system

Overview

It is well known that the exemption around the use of lead in piezoelectric ceramics for ROHS is under review. This is in keeping with the steady removal of lead from a number of consumer applications, back to the removal of lead from paint in the 1960s. Up until now, piezoelectric materials have had an exemption from this legislation, as the standard material used in 90% of all applications is lead zirconium titanate, otherwise known as PZT. The development of lead-free piezoelectric materials has been ongoing in earnest since 2002, however, a number of piezoelectric manufacturers have started introducing lead-free materials to the market to mitigate the risks of changing legislation.Ionix is uniquely positioned to develop and deliver lead-free materials, in that our HPZ series of materials have an unusual combination of high-temperature capability and high piezoelectric activity whilst containing 30% of the lead found in PZT. Presented here is the output of a development project that Ionix have delivered with an industrial consortium to deliver lead-free materials suitable for the extreme environments, in which Ionix specializes.

The Challenge

There are a number of challenges around material development for on-steam ultrasonic transducers which required a solution:

- No commercially available high-temperature lead-free materials existed with an activity >50 pC/N, which limits the applicability of the materials for ultrasonic sensitivity.

- The materials required need to be able to withstand temperature of up to 400 °C (750 °F) continuously for operation in industrial environments such as Energy, Oil and Gas, and Nuclear.

- The material is required to be “plug and play” with current materials – allowing for use of existing manufacturing methods and processes, as well as compatibility with commercial gauges and electronics.

Figure 3: Cycling data of a lead-free HotSense™ probe from 50-400 °C (120-750 °F)

Figure 3: Cycling data of a lead-free HotSense™ probe from 50-400 °C (120-750 °F)

The Solution

- Ionix have developed a unique high-temperature piezoceramic, XLF-580, which operates up to 550 °C (1022 °F) continuously, with similar material properties to Ionix current HPZ 580 material, but contains no lead or rare earth metal oxides making for a sustainable, future-proof supply chain.

- A piezoelectric element of XLF-580 was introduced into Ionix standard HotSense 380, single element 5 MHz transducer, designed for long-term deployment for pipe wall thickness monitoring (Figure 1).

- The transducer offers similar sensitivity and acoustic characteristics to that of a standard HotSense 380 probe (Figure 2).

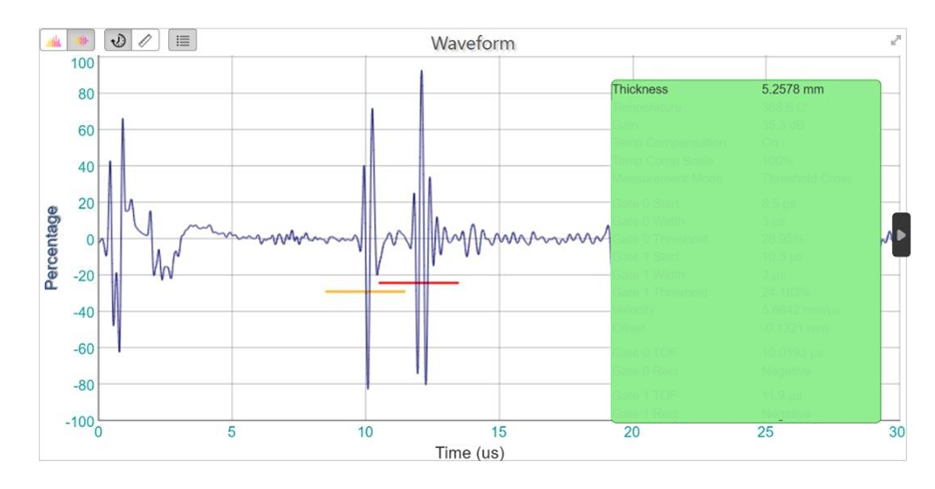

- The transducer was able to successfully track wall thickness with temperature over 50 cycles between room temperature and 400 °C (750 °F) (Figure 3 and 4).

Figure 4: A-Scan captured at ~370 °C (~700 °F)

Figure 4: A-Scan captured at ~370 °C (~700 °F)