Toughness and Machineability – Simplified

Toughness, strength and machineability are key attributes when selecting a piezoceramic for integration into your devices. Many devices require the piezoceramic to be able to withstand high pre-loads or the ceramic may be exposed to high forces during operation. Also, as the piezoelectric resonance and operating frequency of the part is partially determined by the geometry, being able to machine the ceramic to high tolerances can be key. This short blog explores why traditionally used PZT sometimes falls short when it comes to toughness and strength and how a new alternative material, Ionix HPZ, addresses some of these limitations.

When you think of a ceramic, toughness isn’t even a passing thought. We know that ceramics are generally weak, for example, if you drop a cup on the floor that it will smash. This is also true of the most used piezoceramic material, PZT, which is known to have a low fracture toughness and be susceptible to failure under load. What is different with our piezoceramic materials is that it is quiet brittle which can be useful in terms of its strength and machineability.

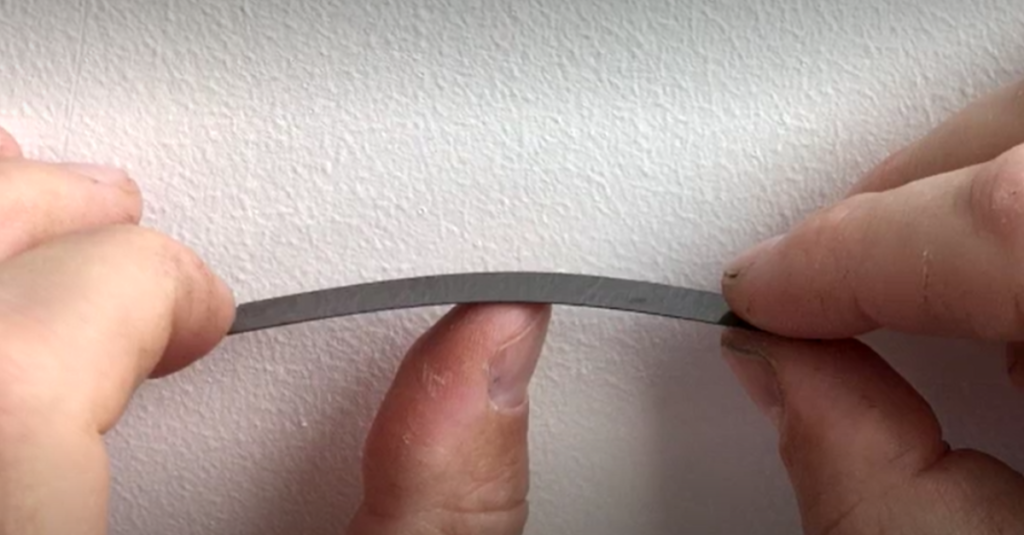

Additionally, HPZ has a strain to failure twice that of PZT, meaning our materials can handle bending and stress much more easily compared to PZT. These attributes allow customers to machine really small features for high frequency arrays, have reliability and longevity, but also withstand large thermal shocks that you see in a number of different sectors.

Contact us for more information in HPZ attributes and abilities or if you would more information on how our materials can level up your sensors, actuators, and devices.