Our HPZ Materials

Ionix has invented a series of proprietary high-performance ferroelectric, piezoelectric materials (HPZTM) which enable devices that can serve a range of demanding environment applications. Our ability to tailor materials optimised for high temperature, high strength and radiation resistance, makes for a versatile technology that is readily manufactured using conventional ceramic production techniques.

Product Performance

Current Piezo (PZT)

Ionix HPZ

Ionix is building on established piezo technology.

The high-performance properties of our ceramics means they are incredibly versatile and can be used for a wide range of applications.

Product Range

HPZ380

The flagship product for high temperature piezoelectrics, HPZ380, is based on Ionix proprietary ceramic composition.

With a higher piezoelectric activity than other materials at these operating temperatures, HPZ380 meets the requirements of the most demanding applications.

Why use HPZ380?

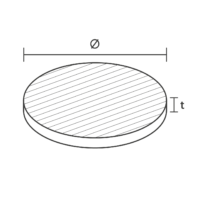

Standard Disc Dimensions

| Frequency (MHz) Diameter (mm) | |||

|---|---|---|---|

| 6.5 | |||

| 10 | |||

| 12 | |||

| 16 | |||

| 30 |

Standard Tolerances

Diameter: ± 0.5mm

Frequency: ± 10%

Thickness: ± 0.05mm

Electrode Materials: Ag, Au

*Tighter tolerances available on request but are dependent on geometry.

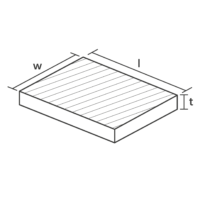

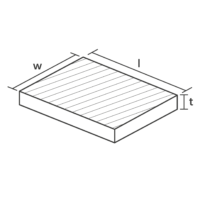

Standard Plate Dimensions

| Dimension | Minimum | Maximum |

|---|---|---|

| Length | 1 | 20 |

| Width | 1 | 20 |

| Thickness | 0.35 | 2 |

Standard Tolerances

Length: ± 0.1 mm

Width: ± 0.1 mm

Thickness: ± 0.05 mm

Electrode Materials: Ag, Au

*Tighter tolerances available on request but are dependent on geometry.

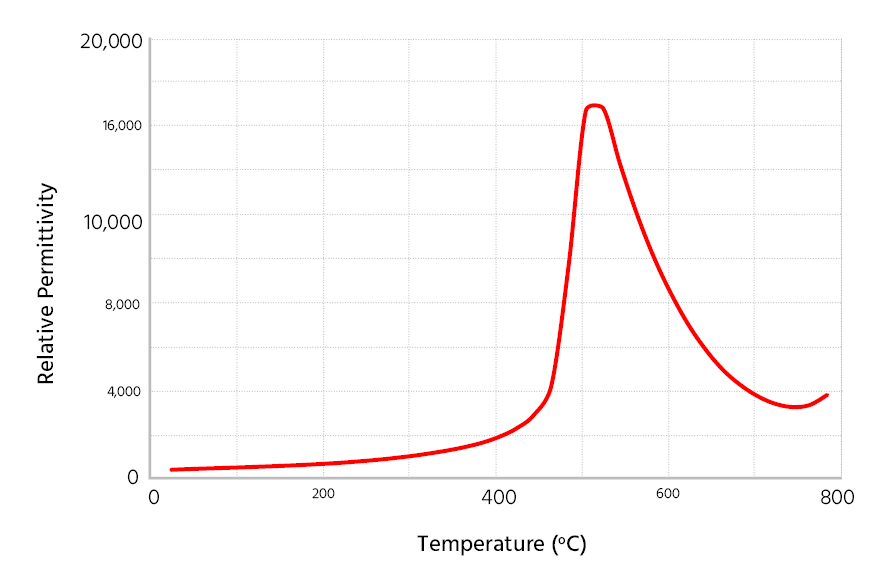

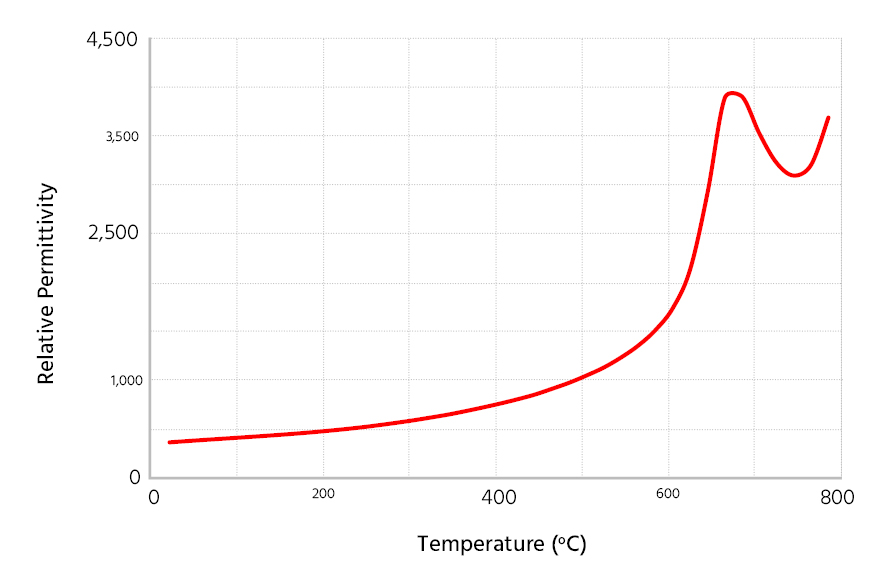

Permittivity – Temperature of HPZ380

How to order HPZ380

HPZ380 ceramics with custom dimensions and electrodes, including wraparound contacts, are also available.

Use our contact form to enquire for standard or custom parts.

HPZ580

A modification of Ionix HPZ380 material, HPZ580 offers an increased operating temperature for a reduction in activity.

HPZ580 can withstand typical bonding temperatures, allowing bonding without requiring repoling of the material, allowing for easy integration into high temperature devices.

Why use HPZ580?

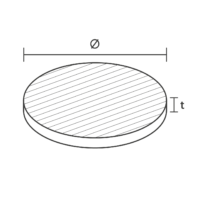

Standard Disc Dimensions

| Frequency (MHz) Diameter (mm) | |||

|---|---|---|---|

| 6.5 | |||

| 10 | |||

| 12 | |||

| 16 | |||

| 30 |

Standard Tolerances

Diameter: ± 0.5mm

Frequency: ± 10%

Thickness: ± 0.05mm

Electrode Materials: Ag, Au

*Tighter tolerances available on request but are dependent on geometry.

Standard Plate Dimensions

| Dimension | Minimum | Maximum |

|---|---|---|

| Length | 1 | 20 |

| Width | 1 | 20 |

| Thickness | 0.35 | 2 |

Standard Tolerances

Length: ± 0.1 mm

Width: ± 0.1 mm

Thickness: ± 0.05 mm

Electrode Materials: Ag, Au

*Tighter tolerances available on request but are dependent on geometry.

Permittivity – Temperature of HPZ580

How to order HPZ580

HPZ580 ceramics with custom dimensions and electrodes, including wraparound contacts, are also available.

Use our contact form to enquire for standard or custom parts.

Product Enquiry

Enquiry Form

HPZ Ceramics FAQ

Yes. HPZ operates in a similar way to PZT and can be utilised using the same control methods. At lower operating temperatures (below 150 C), PZT may be preferable for price sensitive applications where PZT is already suitable, however the unique properties of HPZ can offer advantages even at lower temperatures. We will be happy to discuss your application and advise suitability.

HPZ is currently used in a variety of different applications, such as structural health monitoring (HotSense), flow monitoring, power ultrasound and valve actuation. If you have an application which you think might benefit from HPZ materials, fill in the contact form and our ceramics team will be happy to discuss this with you.

HPZ exhibits a unique combination of high piezoelectric activity and high operating temperature. HPZ operates at temperatures higher than traditional PZT materials, whilst exhibiting higher activity than other high temperature piezoelectrics.

Ionix have developed solutions for bonding HPZ to a variety of materials, such as 300 series stainless steels and titanium, for operation at high temperature. Ionix have also developed HPC, a high temperature piezoelectric composite, for conformal coating of complex geometries.

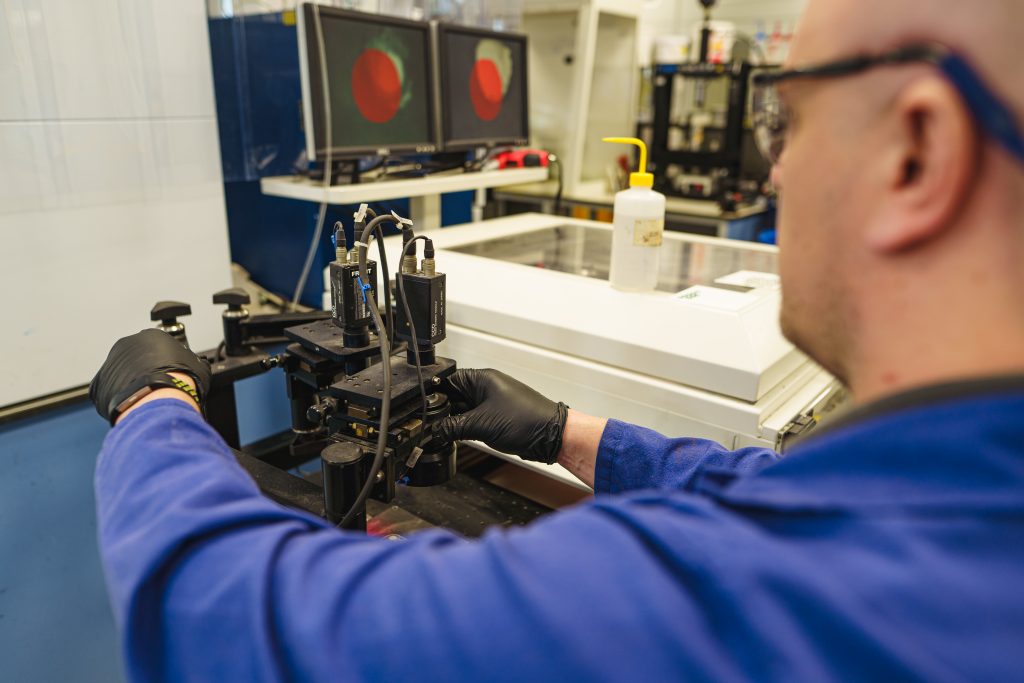

Bespoke Manufacturing

With our advanced ceramic manufacturing facility, we can manufacture piezo-electric materials to order, tailoring their performance for activity, temperature operation, strength or other properties.