CASE STUDY | FUSION H₂ – Breakthrough Hydrogen Flow Sensor

Revolutionizing Hydrogen Measurement with Advanced Ultrasonic Technology

Key Deliverables

- Development of FUSION-H₂ Sensor:

- A groundbreaking ultrasonic sensor designed specifically for hydrogen flow measurement, utilizing lead-free piezoelectric ceramic materials has been developed.

- Addressing Challenges of Lead-Free Ceramics:

- Overcoming poor sensitivity compared to current high-temperature lead-free materials.

- Avoiding high-manufacturing costs and mitigating reliance on rare earth materials.

- Meeting Hydrogen Measurement Requirements:

- Tackling the challenges posed by hydrogen’s high speed of sound, which leads to wide beam spread, increased noise, and low signal strength to provide sensors with high bandwidth and a wide operating temperature range (-200 to +350 °C).

- Testing and Validation:

- Successful construction and testing of prototype sensors in air and helium, with preparations underway for hydrogen testing.

Overview

Ionix are proud to have been chosen as a partner for the UK government’s ‘FutureGrid’ project, to develop the FUSION-H₂ sensor — a novel ultrasonic meter specifically designed for hydrogen flow measurement. This innovative technology, being developed with lead-free piezoelectric ceramic materials, addresses the most pressing challenges in the field, establishing new benchmarks for innovation and precision.

Hydrogen is set to be a key player in the UK’s journey toward net zero, offering low-carbon solutions essential for a deeply decarbonized and renewable energy system. As a versatile alternative to high-carbon fuels, low-carbon hydrogen can significantly reduce emissions across critical UK industrial sectors while providing flexible energy for power, heat, and transport.

The UK is uniquely positioned to foster a robust hydrogen economy, leveraging its vision, resources, and expertise. With world-class innovation, UK companies have the opportunity to thrive in both domestic and global markets. In support of the UK Hydrogen Economy, Ionix aligns its work with the UK Hydrogen Strategy to facilitate the transition to a low carbon energy system, ultimately supporting the country’s net zero commitments. The UK Hydrogen Strategy outlines a roadmap for the 2020s, aiming to achieve a 5GW production target by 2030 and support the nation’s Sixth Carbon Budget and net zero commitments.

The Challenge

Hydrogen is set to become a vital element of sustainable energy in the future, but accurately measuring its flow presents several significant challenges:

- Re-purposing gas networks demands high-fidelity metering for custody exchange and effective leak detection.

- Conventional ultrasonic flow meters struggle with hydrogen due to its high speed of sound (over 1,300 m/s), leading to:

- Wide beam spread

- Increased noise

- Low signal strength

- Future-proofing sensors requires lead-free materials, as legislation is gradually restricting lead use, and PZT, though currently exempt, will inevitably be banned.

- High bandwidth and wide operating temperature range are essential, with requirements spanning from -200 to +350 °C.

- Meeting the milestone set for 2025 to conduct technology testing on FutureGrid, contributing to the development of safe and reliable hydrogen transmission for Project Union.

The Solution

New applications require new materials and solutions, the Ionix platform is specifically designed to overcome the most demanding challenges.

The FUSION-H₂ sensor represents a breakthrough in hydrogen flow measurement, addressing key challenges related to lead-free ceramics, material sensitivity, hydrogen’s high-speed sound, and extreme operational conditions. It aligns with the UK’s hydrogen strategy, supporting both innovation and the nation’s broader net-zero goals:

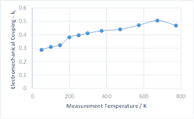

- Increased sensitivity of lead-free ceramics: Overcoming lower sensitivity compared to traditional PZT materials by using Ionix novel lead-free piezoelectric materials.

- Hydrogen’s high speed of sound: Tackling wide beam spread, increased noise, and low signal strength by making the transducer with high frequency, move the previous 20 ~ 50 kHz region to 200 ~ 300 kHz region to:

- Increase directivity

- Maintain the size of the probe to make it compatible with previous infrastructure

- Higher bandwidth allowing effective cross-correlation signal processing technique using chirp signals to

increase Signal-to-Noise Ratio (SNR).

- Material integration: Adapting sensor design to hydrogen’s unique properties, by removing organic material from the design to prevent embrittlement as a result of hydrogenation, giving the probe greater resilience to hydrogen.

- Cost and resource management: By employing new lead-free materials, the solution minimizes manufacturing costs and reduces reliance on rare earth materials.

- Wide temperature range: Continuous sensor functionality across extreme temperatures (-200°C to +350 °C).

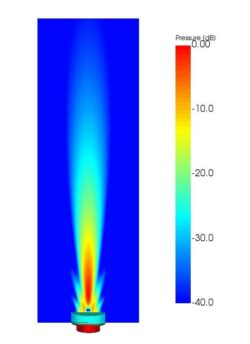

The image shows a plot of the beam profile in hydrogen gas. A graphical representation of the distribution of intensity across a beam of light or other electromagnetic radiation, showing how the energy is spread along the beam’s cross-section – a glimpse into our progress so far.

Execution

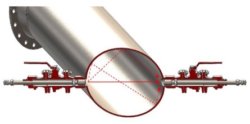

As the UK transitions to hydrogen, it’s vital to prepare our gas infrastructure for this shift. FutureGrid at DNV Spadeadam is conducting tests with hydrogen in high-pressure environments using decommissioned assets. These tests will inform the development of safe and reliable hydrogen transmission for Project Union.

The Ionix team is dedicated to addressing the challenges of hydrogen flow measurement and providing innovative solutions for OEMs. As hydrogen adoption becomes more widespread, ensuring our gas infrastructure is equipped to handle these changes is crucial. Ionix has successfully built and tested initial prototype sensors in air and is now preparing for hydrogen testing. Our next milestone is set for 2025, when we will test this technology on FutureGrid, continuing to push the boundaries of innovation.